Thin-Wall Plastic Injection Molding Machine

EHIII-DS Series (50~750 TON)

Thin-wall plastic injection molding machine is manufactured by increasing the injection speed and the stability of injection, the thin-wall injection machines effectively avoiding short shots and flashes on the product to improve product quality.

We upgrade the thin-wall injection machines control components to get a higher injection speed that ensures the injected melting plastic material could reach the entire mold cave before it getting solidification which decreases the short-shot products happened.

If you need more detail of product information or buying consultation, please contact us.

Plastic injection machine, Injection Molding Machine for plastics

To maintain the stability of the injection, we use a servo valve to make a closed-loop injection system and control the injection pressure and flow-rate individually. Even if under a high-pressure and high-flow condition it keeps the injected volume has the same output in every production cycle to prevent the flashing or short shot of the products happened.

Plastic Injection Molding Machine Core Features

- Clamping force from 50ton - 750ton.

- Upgrade the injection control components to get a higher injection speed and ensure stability.

- With the Rexroth servo-valve and the Injection Molding Process Controller, rapid response time.

- Multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise.

- Independent accumulator pump.

- OLAER pressure accumulator.

- Maximum injection speed rate is up to 360mm/sec.

Your Benefits of purchaseing Plastic Injection Molding Machine

- Shorten the production cycle time, increasing the production yield.

- Under the accumulator assisted the maximum injection speed rate reaches 360mm/sec it's fitting to make many kinds of thin-wall products.

- More accurate to switch inject position into hold pressure to prevent over injection causes the flash of products.

Our Advantage

- The thin-wall injection machine comes standard with a high-performance close-loop energy-saving servo motor, compared with conventional motor save energy by 60%.

- The accumulator pump unit helps the accumulator to be pressurized directly, during this period the main pump enables to continue the next processes, saving the for pressuring the accumulator time. The production cycle will be greatly shortened.

- Each pressure accumulator has CE certification with high safety and stable pressure releasing performance.

Thin-Wall Plastic Injection Molding Machine Video

Related Application

Thin-wall injection molding machine widely used in food packaging, medical and 3C electronics industries.

- Product Application

- Specification Table

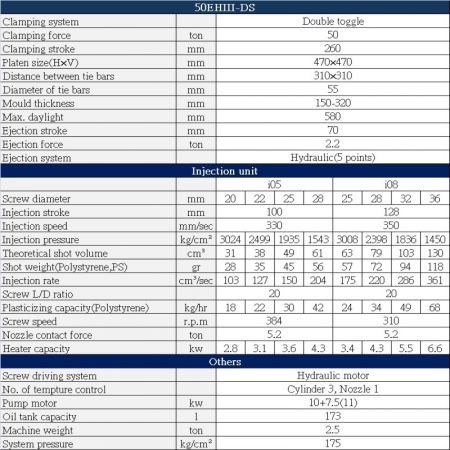

- EHIII-DS 50 ton Specification Table

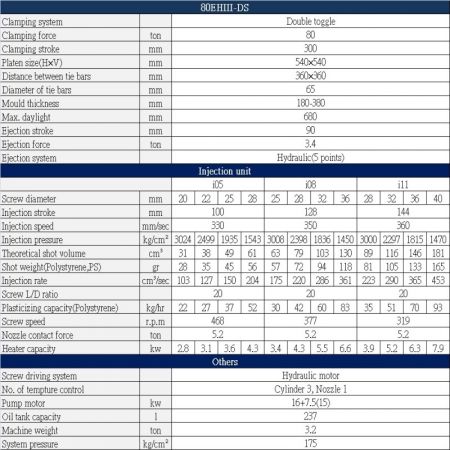

- EHIII-DS 80 ton Specification Table

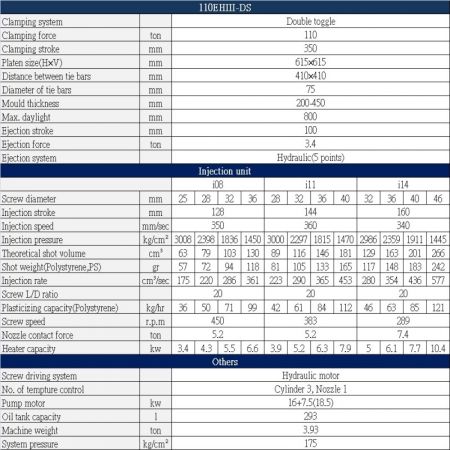

- EHIII-DS 110 ton Specification Table

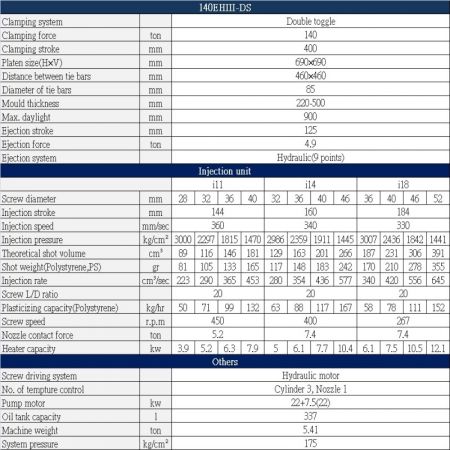

- EHIII-DS 140 ton Specification Table

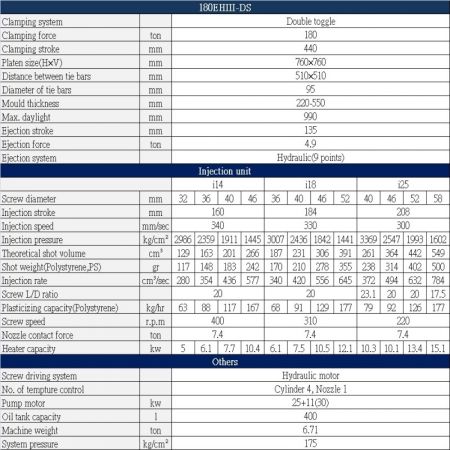

- EHIII-DS 180 ton Specification Table

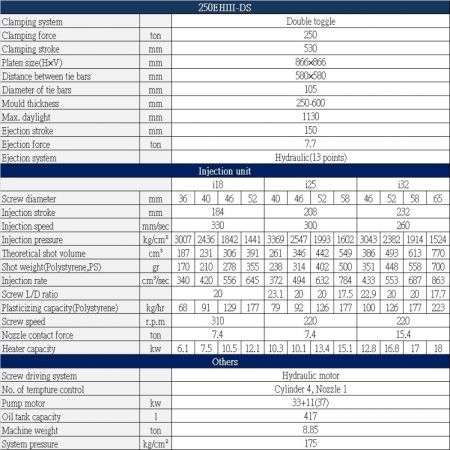

- EHIII-DS 250 ton Specification Table

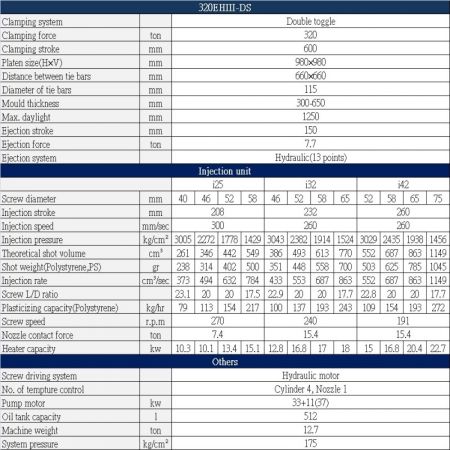

- EHIII-DS 320 ton Specification Table

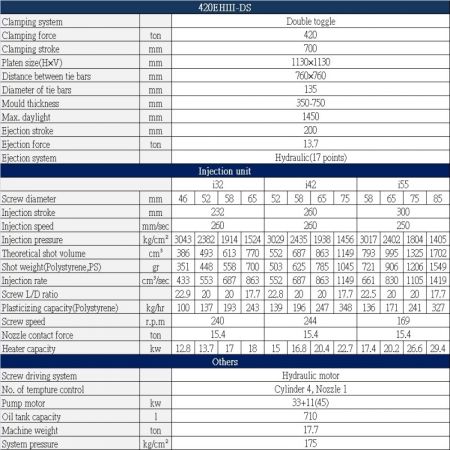

- EHIII-DS 420 ton Specification Table

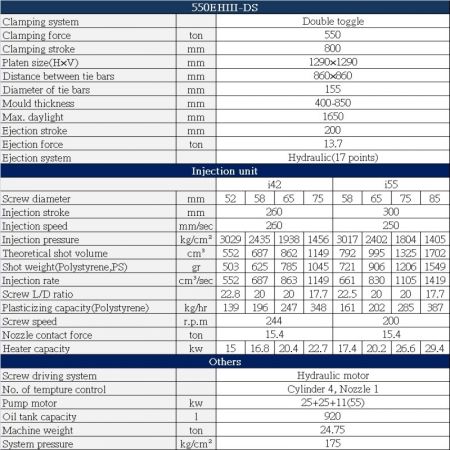

- EHIII-DS 550 ton Specification Table

- Related Products

Small Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (50~140 TON)

The 50 ton to 140 ton High-Speed Hybrid Plastic Injection Machine with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.

Small Size High Speed Plastic Injection Molding Machine

EHIII SERIES (50~140 Ton)

The small high-speed plastic injection molding machine is from 50 tons to 140 tons. It comes standard with a high-response servo valve and accumulator. During the assistance with the accumulator, the injection rate can reach 360mm/sec. The high-response servo valve detects the actual pressure and position of the injection by the transducer and then catches the feedback signal to adjust the output to reach a perfect closed-loop control. By the precision control of the injection, plasticizing, and holding switch-over to prevent causing flash or short-shot. If you need more detail of product catalog, please reach out to us.

- Files Download

EHIII-DS EHIII OS-50-110 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.

EHIII-DS EHIII OS140-250 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.

EHIII-DS EHIII OS320-550 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.