Small Size High Speed Hybrid Plastic Injection Molding Machine

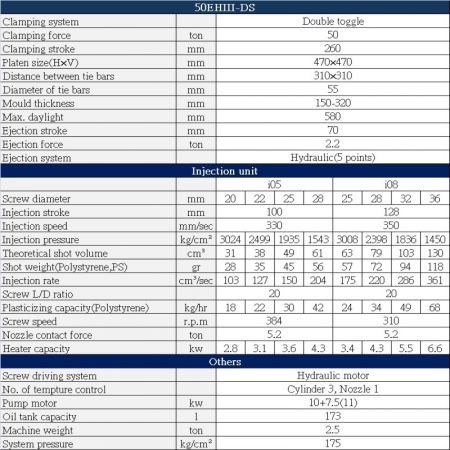

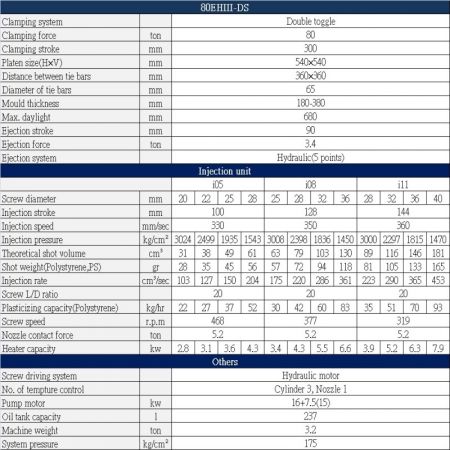

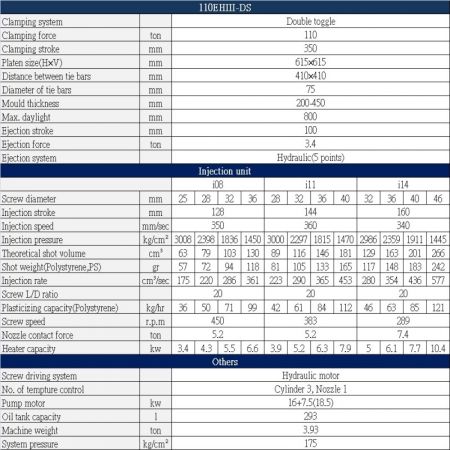

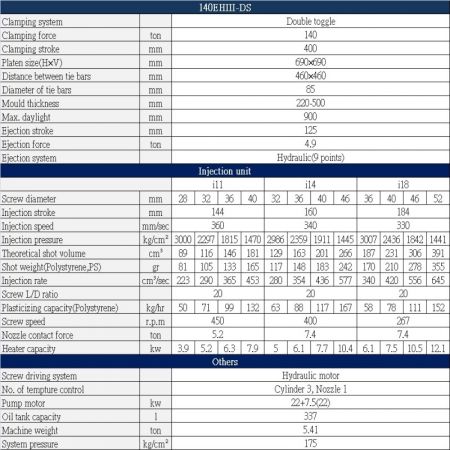

EHIII-DS Series (50~140 TON)

The 50 ton to 140 ton High-Speed Hybrid Plastic Injection Machine with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.

Servo Hydraulic Injection Molding Machine, Plastic Injection Machine, Injection Molding Machine for Plastics

Under the accumulator assisted the maximum injection speed rate reaches 360mm/sec it's fitting to make many kinds of thin-wall products. Due to the high response and feedback features, it more accurate to switch inject position into hold pressure to prevent over injection causes the flash of products.The Accumulator Pump gives an advantage during the accumulator is pressurized. The pump provides the extra flow to pressurize the accumulator directly, therefore the main system won't stop during the accumulator gets pressurized to shorten the production cycle time.

Plastic Injection Molding Machine Core Features

The Small Size High Speed Hybrid Injection Molding Machine with dual hydraulic cylinders has clamping force from 50ton - 140ton. The response time of servo from 0% to 100% only needs 26ms. Maximum injection speed rate is up to 360mm/sec. The injection molding machine has Independent accumulator pump and OLAER pressure accumulator.

Major Benefits of Plastic Injection Molding Machine

- High-speed injection, maximum capacity.

- Save 60%~80% power consumption.

- Low noise, only 63 dBs under oil pressure of 140kg/cm².

- Significantly reduce mechanical maintenance costs.

The Performance Characteristics of Plastic Injection Molding Machine

Top Unite provides injection machines that come standard with a closed-loop control system and a high-performance energy-saving servo motor, it advantages a low power consumption compared with a conventional motor. In high-speed machines, we configure a booster pump. The main function is to pressurize the accumulator, this device is independent of the main hydraulic system, thus during the pressurizing, the main pump is able the machine to continue the next molding step, saving for pressuring the accumulator time to bring more productivity.

The platen uses the FCD-600 spheroidal graphite cast iron, which can bear high pressure from the injection, it avoids bending or deforming causes flash on the products. Top Unite provides s-60c high carbon steel slides that work with the roller bearing to carry the movable platen and match with a proportional valve to control platen moving, even the machine is installing a heavy mold, it brings smoothness and increases the stability of the location point.

The Mold Adjustment Mechanism with sturdy gear has high strength and low clearance features, which increases the accuracy of clamping location. We also build a hydraulic motor with a brake unit to provide the power to the mold adjustment. With the brake unit, it helps you to avoid mold thickness change during production, to give you a stable and effective output.

Related Application

It is suitable for thin-walled or frame products such as food containers and panel frames, which are large injection area but with a small injection amount.

- Specification Table