FAQ

Frequently asked questions

Top Unite technical team has abundant experience in the plastic injection molding market and is committed to assisting customers in troubleshooting production problems. If you have any questions about our products, you can refer to the FAQ section. We collected and organized the frequent questions asked by customers and provided detailed instructions so that customers can quickly and more deeply understand the features and advantages of Top Unite various series of plastic injection molding machines, as well as our professional, immediate, and reliable services. Through the Q&A, you will be able to more easily choose the best plastic injection molding solution.

What industries are plastic injection molding machines suitable for?

Top Unite plastic injection molding machine has excellent injection performance, multiple unique hydraulic techniques, and sturdy, reliable clamping structure, is suitable for the production of various types of plastic products on the market, include automobile accessories, medical supplies, consumer electronic product, sports equipment, household appliances, food packaging containers, precision optics, engineering plastic, power tool housing, and industrial pipes.

Why is the injection molding performance so important?

Top Unite plastic injection molding machine has excellent injection performance, with high production output rate, makes our client's project work more efficient.To meet every client in different industries, Top Unite launches several high-performance injection molding machines, based on the different injection processes, we separate the injection machines into horizontal, two-color, and vertical.Our main product is horizontal injection machines, the clamping force is from 50ton to 750ton (500kN~7500kN), it distinguishes four series according to motor type and injection speed.

How does plastic injection machine achieve high performance, high precision and high stability?

Top Unite full range of plastic injection molding machines are high-performance machines, with excellent injection performance, more accurate shooting stroke, the mechanical operation is extremely stable, high repeatability, and low maintenance rate, longer service life, not only to fully meet the needs of all types injection molding industry but also to significantly reduce customer production costs.

How to avoid plastic injection machine to cause flash to product?

The problem of causes flash to the products is a lot, the key factor is the strength of the platen. If the platen is not strong enough to resist the pressure from the injection, it will cause the gap by the platen deforming, and this gap leads to melting plastic leaked that causes the flash to the products.To ensure the strength of the template to meet injection molding needs in different industries, Top Unite full range of injection molding machines uses high-rigidity platen, using FCD-600 spherical graphite cast iron, which can achieve a high tensile strength of 600~750 N/mm². Even under extremely high injection pressure and speed conditions, the platen will not be deformed or broken to avoid the product flash, improve the product quality, and prolong the machine's lifetime.

What kind of services can I expect from purchasing injection machine?

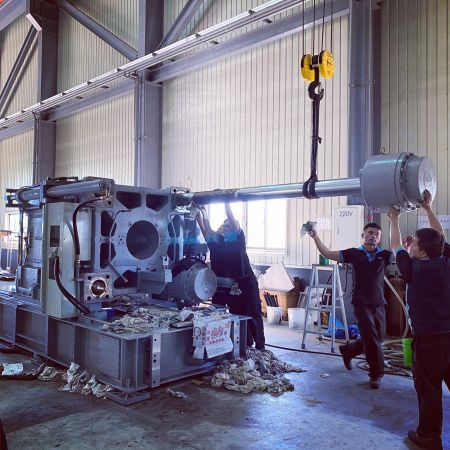

Generally, customers with injection molding experience have the ability to adjust the machine to the best production state. For this type of customer, after the machine assembling and testing, it can be handed over. However, some customers may lack injection molding experience, or they may be foreign customers. Top Unite assists in purchasing axillary equipment, such as a robot arm, molds, in-mold labeling, packaging machines, etc..., this kind of customer will want Top Unite to integrate the equipment into the injection machine and conducts trial production to confirm that the different equipment can be perfectly integrated and the production line goes smooth and unimpeded. After the injection machine is delivered, it can be put into production immediately.

What are the successful cases of Top Unite plastic injection molding machine?

Top Unite injection machine famous in the plastic injection industry for its high performance, high precision, and high stability. Top Unite has piled up over 40 years in the plastic injection molding industry and earned solid practical experience and the plastic injection technique. Therefore we are not only Taiwan's leading supplier of injection molding machines, but also expand the market to all over the world.

What are the features and advantages of a toggle type injection molding machine?

Top Unite full range of plastic injection machines are toggle injection molding machines. The clamping way of the toggle system is using an oil cylinder as a power source to bring the toggle to open and close the platen. Due to the different angles to the toggle position has a decelerate interval before the mold touchpoint that can literally give safety to the mold.

What is the difference between an energy-saving injection machine and a traditional injection machine?

Comparing with energy-saving injection machines and traditional machines is a different type of power source, one is a servo motor the other is an induction motor. The biggest difference between the induction motor and servo motor is the way to building pressure.