High-Speed Plastic Injection Molding Machine Doubles Capacity for Customer in Peru, Winning Orders from Fast Food Giants

With upgraded machines, our customer became a leader in the market and successfully captured the disposable plastic tableware market

Top Unite provided a high-speed plastic injection molding machine designed for a manufacturer of disposable plastic tableware in South America. This upgrade helped the customer double their production capacity and quickly gain the trust of major global fast food chains, securing multiple large orders. Our team provided complete technical support, which included improving the injection units, optimizing mold designs, enhancing cooling systems, and introducing servo motors. This led to production cycles being reduced by more than half. Our tailored solutions not only maximized production efficiency but also guaranteed consistent product quality for every unit.

CUSTOMER BACKGROUND AND CASE DESCRIPTION

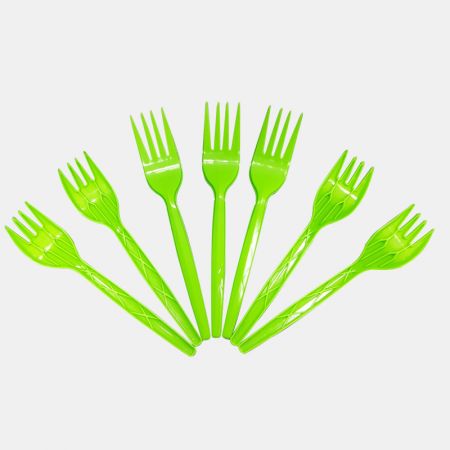

Our customer is located in South America and specializes in making high-quality disposable plastic tableware, like spoons, forks, and cups. Their old machines could not meet market demands, leading to long production times and inconsistent product quality, which hurt their competitiveness. A mold manufacturer recommended they contact Top Unite for a solution to improve capacity and quality.

The major problems to this client are improving the yield rate and shorten the circle of the production. In this case study, Top Unite separates the situation into three major parts and bases the problems they were facing to give solutions to achieve their needs.

Increasing the Number of Mold Cavities and Upgrading the Injection Unit

We redesigned the mold to include more cavities, enabling the production of more units per cycle. To support this change, we upgraded the injection unit and incorporated a pressure accumulator to boost injection speed. This ensured that molten plastic filled all cavities evenly and accurately before solidifying.

Enhancing the Cooling System

To shorten cooling times and increase overall production efficiency, we integrated advanced chillers into the cooling system. This improvement significantly reduced the production cycle time.

Replacing Hydraulic Motors with Electric Servo Motors

We replaced the traditional hydraulic charge motor with an electric servo motor, which enhanced precision and reduced energy consumption by 70%. Additionally, we installed a shut-off nozzle on the material barrel to prevent molten plastic from spilling into the mold during the charging process. This design allowed the machine to charge and open the mold simultaneously, further reducing cycle times and improving operational efficiency.

These changes helped the customer increase their production, reduce cycle times, and improve product quality, making them a leading supplier of disposable plastic cutlery in the local fast food market.

WHY CUSTOMERS CHOOSE OUR INJECTION MOLDING MACHINES

Top Unite not only sells efficient injection machines but also provides complete plastic injection molding solutions. When customers first buy our machines, they may not be familiar with how they work, especially when setting up production parameters.

To help with this, our technical team communications with customers to check and adjust every parameter setting to make sure the injection conditions meet product needs perfectly. We guide customers through the whole process, helping them quickly learn to operate the machines and improve their performance. This support not only shortens production times but also helps customers maximize their capacity and maintain high-quality products.

CUSTOMER FEEDBACK

With the help of Top Unite's professional team, the customer's production capacity doubled, securing orders from major fast food companies in South America. These results showed the customer how important efficient machines are for production and competitiveness. They now consider Top Unite a long-term strategic partner, confident in achieving sustained growth.

If you’re looking to upgrade your injection molding operations and achieve similar success, contact Top Unite today for a tailored consultation!

- Servo Energy-Saving Plastic Injection Molding Machine, Ship to Peru.

- High Speed Injection Molding Machine Product-Plastic Fork and Plastic Spoon

- Top Unite Injection Molding Machine Produce High-Quality Plastic Tableware

- Related Products

Small Size High Speed Plastic Injection Molding Machine

EHIII SERIES (50~140 Ton)

The small high-speed plastic injection molding machine is from 50 tons to 140 tons. It comes standard with a high-response servo valve and accumulator. During the assistance with the accumulator, the injection rate can reach 360mm/sec. The high-response servo valve detects the actual pressure and position of the injection by the transducer and then catches the feedback signal to adjust the output to reach a perfect closed-loop control. By the precision control of the injection, plasticizing, and holding switch-over to prevent causing flash or short-shot. If you need more detail of product catalog, please reach out to us.

Small Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (50~140 TON)

The 50 ton to 140 ton High-Speed Hybrid Plastic Injection Machine with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.

Medium and Large Size High Speed Plastic Injection Molding Machine

EHIII SERIES (180~750 Ton)

The High-speed plastic injection molding machine features 180 ton to 750 ton medium and large size and reaches the 360mm/sec injection speed rate by the assist of the accumulator. To control the flow from the accumulator, we use a servo valve to inject, charge and switch the holding pressure point, which makes sure every single injection could inject the same volume of plastic to prevent the flashing or short shot of the products. If you need more detail of product information or buying consultation, please contact us.

Medium and Large Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (180~750 TON)

The High-Speed Hybrid Plastic Injection Machine is designed with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.