Medium and Large Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (180~750 TON)

The High-Speed Hybrid Plastic Injection Machine is designed with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.

Plastic Injection Machine with the servo valve, accumulator and energy-saving motor, Horizontal Injection Molding Machine

Under the accumulator assisted the maximum injection speed rate reaches 360mm/sec it's fitting to make many kinds of thin-wall products. Due to the high response and feedback features, it more accurate to switch inject position into hold pressure to prevent over injection causes the flash of products.The Accumulator Pump gives an advantage during the accumulator is pressurized. The pump provides the extra flow to pressurize the accumulator directly, therefore the main system won't stop during the accumulator gets pressurized to shorten the production cycle time.

Plastic Injection Molding Machine Core Features

- Clamping force from 180ton - 750ton.

- Injection with dual hydraulic cylinders.

- Response time of servo from 0% to 100% only needs 26ms.

- Maximum injection speed rate is up to 360mm/sec.

- Independent accumulator pump.

- OLAER pressure accumulator.

- High speed and low energy consumption.

Your Benefits of purchaseing Plastic Injection Molding Machine

- High-speed injection, maximum capacity.

- Save 60%~80% power consumption.

- Low noise, only 63 dBs under oil pressure of 140kg/cm².

- Significantly reduce mechanical maintenance costs.

- Top Unite use Bosch Rexroth Servo Valve as the injection molding machine parts.

- Plastic Injection Molding Machine Parts-Rexroth Injection Molding Process Controller Card

Our Advantage

- Plastic injection molding machine comes standard with high-performance close-loop energy-saving servo motor, compared with conventional motor save energy by 60%.

- Accumulator pump unit helps the accumulator to be pressurized directly, during this period the main pump enables to continue the next processes, saving the for pressuring the accumulator time. The production cycle will be greatly shortened.

- Each pressure accumulator has CE certification with high safety and stable pressure releasing performance.

- The s-60c high carbon steel slide matched the roller bearing reduces the friction and brings smooth during mold opening and clamping.

- Mold open/clamping switch is controlled by a proportional solenoid valve increase the stability of the platen location point.

- The platen uses the FCD-600 spheroidal graphite cast iron could achieve 600 ~ 750 N/mm² tensile strength not easy to bend or deform.

- The toggle automatic centralized lubrication system, always keeps the toggle and copper bushing parts lubricated to increase the life-time.

- The Mold Adjustment Mechanism with sturdy gear and high torque hydraulic motor has high strength and low clearance, which reduces adjusting time and increases accuracy.

- Mold Adjustment Motor with Brake Unit always keeps the platen in the same position prevents to cause the flash of the products.

Medium and Large Size High Speed Hybrid Plastic Injection Molding Machine Gallerys

- FCD-600 spheroidal graphite cast iron with thicker plate

- AC Permanent Magnet Servo Motor And Voith Internal Gear Pump

- Top Unite use OLAER Hydraulic Accumulator as the injection molding machine parts

- Amplifier for Yuken Proportional Solenoid Valve

Related Application

Plastic Injection Molding Machine is suitable for thin-walled or frame products such as food containers and panel frames, which are large injection area but with a small injection amount.

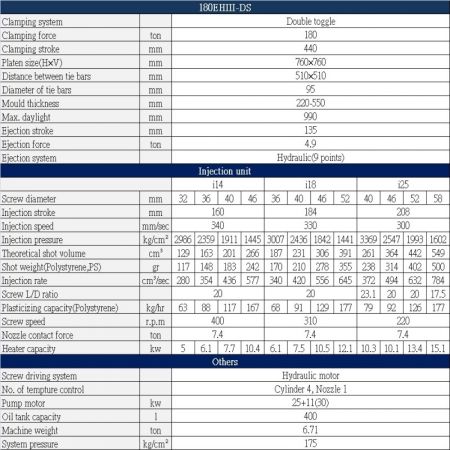

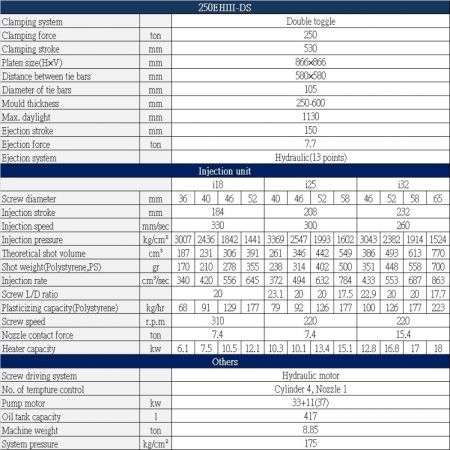

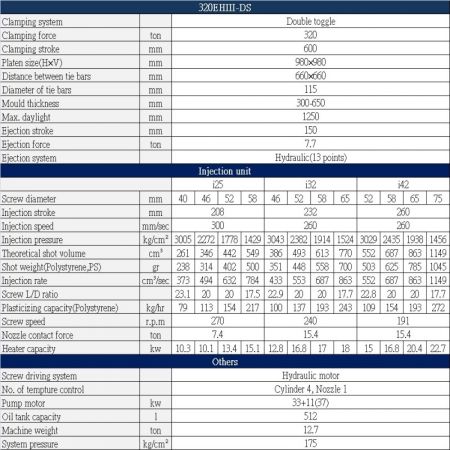

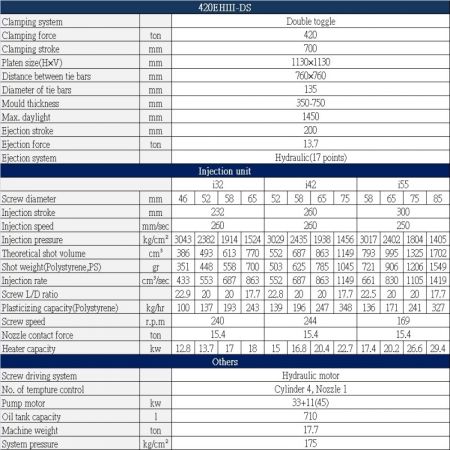

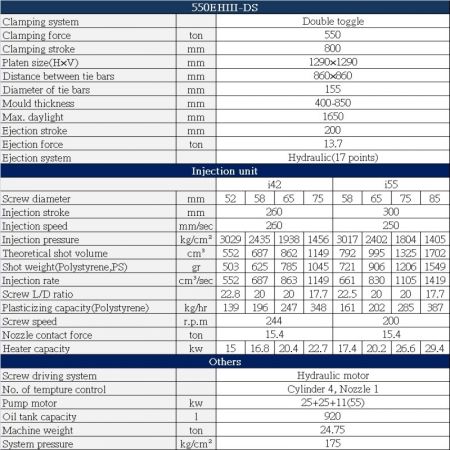

- Specification Table

- Related Products

Small Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (50~140 TON)

The 50 ton to 140 ton High-Speed Hybrid Plastic Injection Machine with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.

Small Size High Speed Plastic Injection Molding Machine

EHIII SERIES (50~140 Ton)

The small high-speed plastic injection molding machine is from 50 tons to 140 tons. It comes standard with a high-response servo valve and accumulator. During the assistance with the accumulator, the injection rate can reach 360mm/sec. The high-response servo valve detects the actual pressure and position of the injection by the transducer and then catches the feedback signal to adjust the output to reach a perfect closed-loop control. By the precision control of the injection, plasticizing, and holding switch-over to prevent causing flash or short-shot. If you need more detail of product catalog, please reach out to us.

- Files Download

EHIII-DS EHIII OS-50-110 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.

EHIII-DS EHIII OS140-250 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.

EHIII-DS EHIII OS320-550 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.