Polycarbonate Plastic Injection Molding Machine

EH-DS Series (50~750 TON)

Plastic Injection molding machine has directed the characteristic of polycarbonate, strengthens the injection unit to get higher injection pressure that maintains a stable production and effectively preventing wavy or streaks caused on the product surface.

This series of models build-in a Polycarbonate-transparent special-purpose material barrel, which surfaces with the chromium plating process, and an exclusive L/D ratio design, to prevent black spots and yellowing on the product and improve production quality.

If you need more detail of product information or buying consultation, please contact us.

Polycarbonate-transparent products injection molding machine

Plastic Injection Molding Machine Core Features

- Clamping force from 50ton - 750ton.

- Upgrade the injection-unite by enlarging the inject piston section area thereby bringing greater injection pressure.

- The build-in Polycarbonate-transparent special material barrel.

- Material barrel with the chromium plating process and exclusive L/D ratio design.

- Closed loop system equipped with Toshiba servo system.

- Customize to upgrade the motor output, increase the system flow.

Your Benefits of purchaseing Plastic Injection Molding Machine

- High injection pressure used with a special barrel design prevents black spots, yellowing, wavy or streaks caused on the product surface.

- Energy-saving at least 60% compared with conventional motor. (Reduce power consumption by 60%.)

- Quick and Easy to integrate to the automated production equipment.

- Fast response and precision.

- Significantly reduce machine maintenance costs.

Our Advantage

- DS series injection machine comes standard with high-performance close-loop energy-saving servo motor, compared with conventional motor save energy by 60%.

- The platen uses the FCD-600 spheroidal graphite cast iron could achieve 600 ~ 750 N/mm² tensile strength not easy to bend or deform.

- The toggle automatic centralized lubrication system, always keeps the toggle and copper bushing parts lubricated to increase the life-time.

- Dual injection cylinders mechanism provides high-pressure and high-speed injection, match with the high response valve upgrade the performance of injection.

- The Mold Adjustment Mechanism with sturdy gear and high torque hydraulic motor has high strength and low clearance, which reduces adjusting time and increases accuracy.

- Mold Adjustment Motor with Brake Unit always keeps the platen in the same position prevents to cause the flash of the products.

- The s-60c high carbon steel slide matched the roller bearing reduces the friction and brings smooth during mold opening and clamping.

- Mold open / clamping switch is controlled by a proportional solenoid valve increase the stability of the platen location point.

Related Application

Polycarbonate injection molding machine is suitable for the production of transparent polycarbonate plastic products such as automobile lamp shells, fisheye headlights, cosmetic containers, and diving goggles lenses.

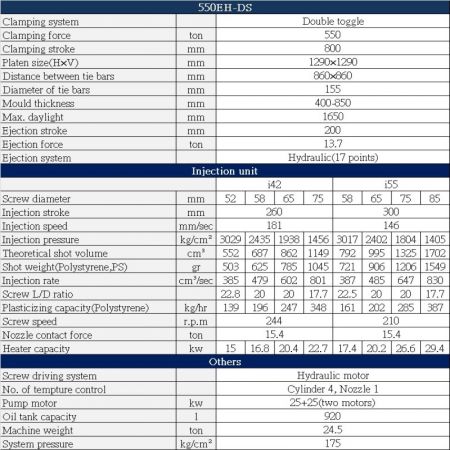

- Specification Table

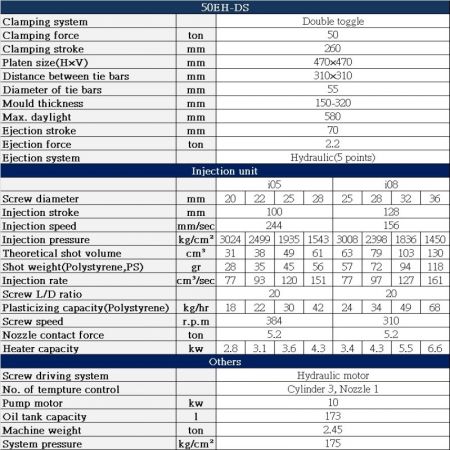

- EH-DS 50 ton Specification Table

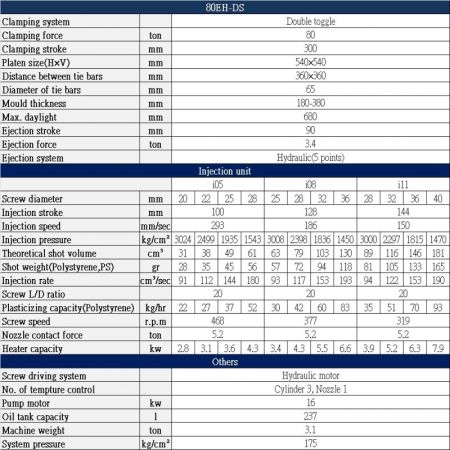

- EH-DS 80 ton Specification Table

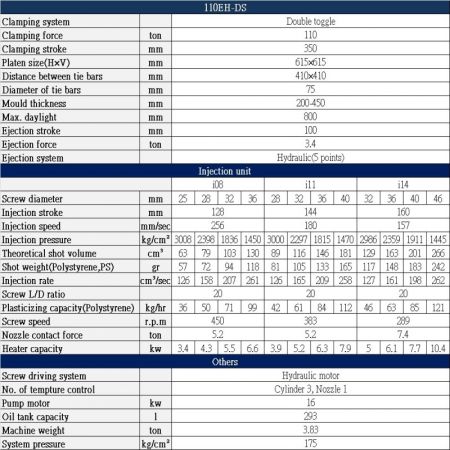

- EH-DS 110 ton Specification Table

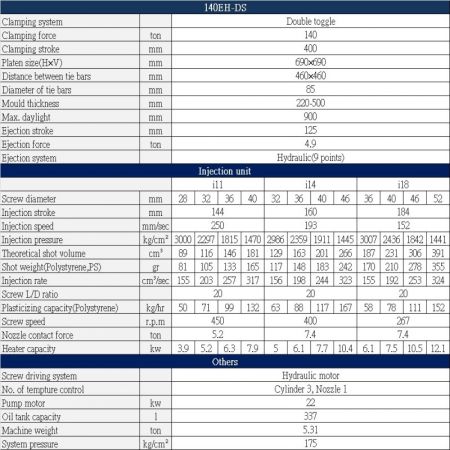

- EH-DS 140 ton Specification Table

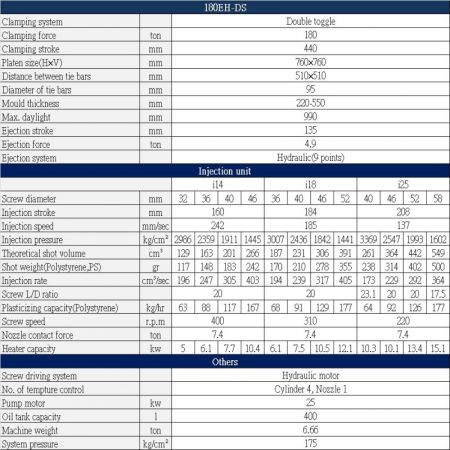

- EH-DS 180 ton Specification Table

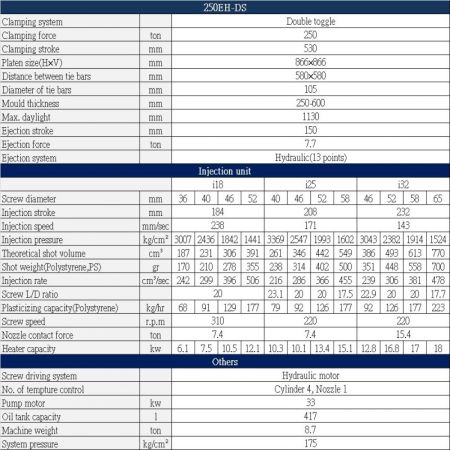

- EH-DS 250 ton Specification Table

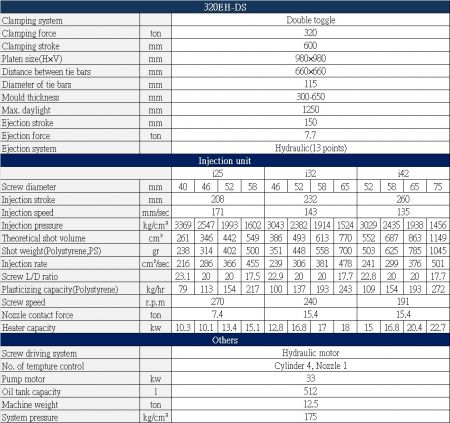

- EH-DS 320 ton Specification Table

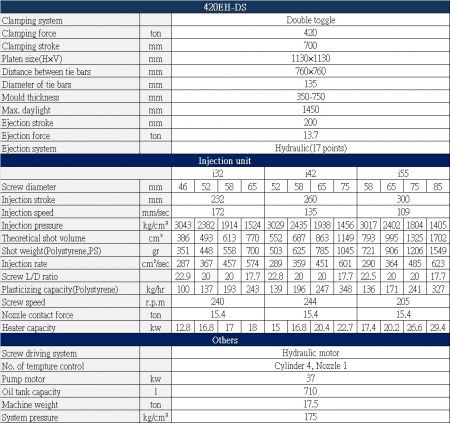

- EH-DS 420 ton Specification Table

- EH-DS 550 ton Specification Table

- Related Products

Medium and large size Hybrid Plastic Injection Molding Machine

EH-DS Series (180~750 TON)

The Hybrid Plastic Injection molding machine (180ton to 750ton medium and large size) equips a high-performance servo motor, which also achieves an outstanding energy-saving effect. With a rapid response and pressure output linear feature, easy to reach every requirement given by the user. It reduces the motor r.p.m when during the low flow is required and the product cooling to save the energy consumption. Comparing with the conventional hydraulic injection machine, it saves 60% energy at least.

Small Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (50~140 TON)

The 50 ton to 140 ton High-Speed Hybrid Plastic Injection Machine with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.

- Files Download

EH-DS 50-110 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.

EH-DS 140-250 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.

EH-DS 320-550 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.