Plastic-Caps Special Plastic Injection Molding Machine

EH-DS Series (50~750 TON)

Plastic-cap special plastic injection molding machine is designed against the food packaging industry. The machine builds in a PP and PE special double thread material barrel. It helps to compound with color masterbatch during the material is plasticizing to reduce the defective products.

To save more time, we place a proportional valve to boot up the speed in the mold closing/opening and make it more accurate to protect your mold. Meanwhile, we strengthen the clamping toggle structure to bear the high pressure from high-speed mold closing/opening which extends the service life. If you need more detail of product information or buying consultation, please contact us.

Plastic injection machine, Injection Molding Machine for plastics

Plastic Injection Molding Machine Core Features

- Closed loop system equipped with Toshiba servo system.

- Builds in a PP and PE special double thread material barrel.

- Customize to upgrade the motor output, increase the system flow.

- Quick and Easy to integrate to the automated production equipment.

Your Benefits of purchaseing Plastic Injection Molding Machine

- Could integrate with CCD inspection and implantation machine, provide automation solution.

- Achieve the purpose of industry optimization and have a leading production level in the industry.

- Meet customer requirements for accuracy and yield of the production.

- Energy-saving at least 60% compared with conventional motor. (Reduce power consumption by 60%.)

Our Advantage

- DS series injection machine comes standard with high-performance close-loop energy-saving servo motor, compared with conventional motor save energy by 60%.

- The platen uses the FCD-600 spheroidal graphite cast iron could achieve 600 ~ 750 N/mm² tensile strength not easy to bend or deform.

- Mold Adjustment Motor with Brake Unit always keeps the platen in the same position prevents to cause the flash of the products.

- The mold open/clamping switch is controlled by a proportional solenoid valve to increase the stability of the platen location point.

- Set a proportional valve to increase the speed of mold closing/opening, shorten the production cycle, and still ensure the stable position of the mold under high-speed operation. Please see the video introduction below.

Plastic-Caps Special Plastic Injection Molding Machine Video

Related Application

Every kind of PP/PE cap, such as: water bottle, seasoning container, hot-fill bottle, etc.

- Product Application

-

-

Plastic-caps injection molding machine is able to produce high-quality bottle caps.

-

Plastic-caps injection machine is easy to integrate to the automated production equipment.

-

Injection machine has excellent performance in injection speed, operation stability and accuracy.

-

The caps made by the plastic-caps injection machine have a stability quality and precision size.

-

- Specification Table

-

-

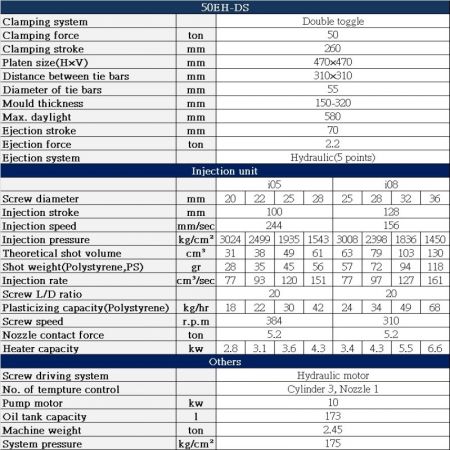

EH-DS 50 ton Specification Table

-

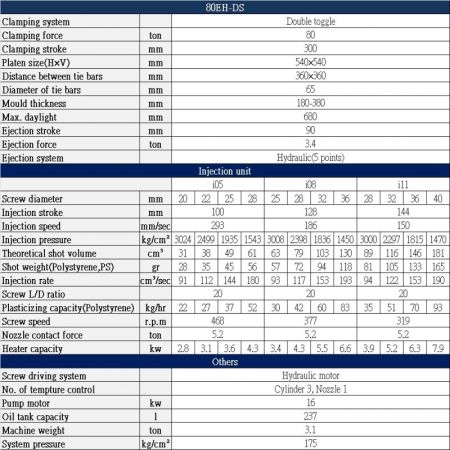

EH-DS 80 ton Specification Table

-

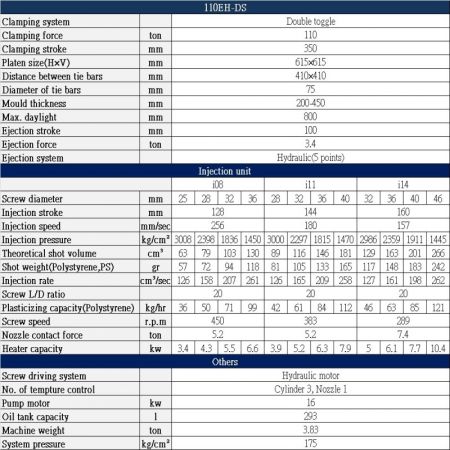

EH-DS 110 ton Specification Table

-

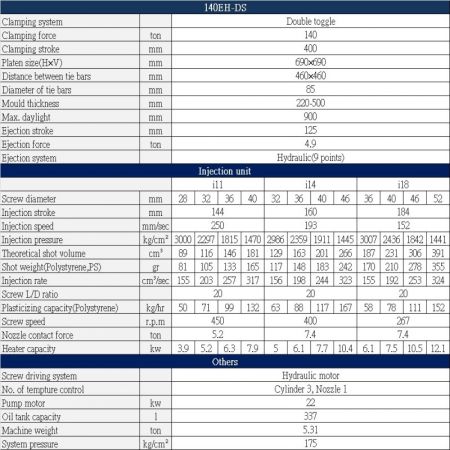

EH-DS 140 ton Specification Table

-

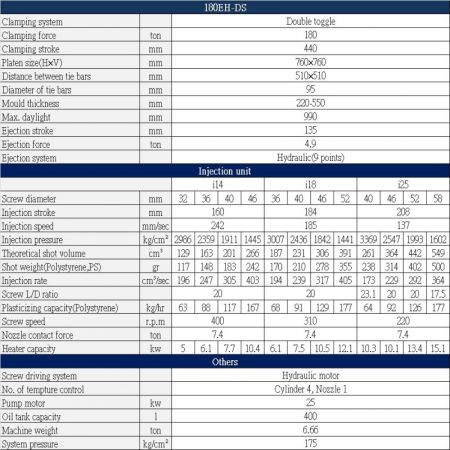

EH-DS 180 ton Specification Table

-

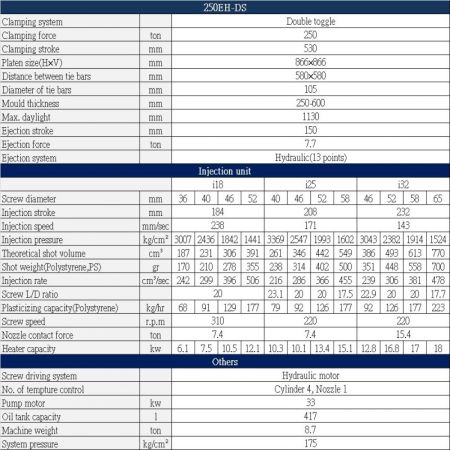

EH-DS 250 ton Specification Table

-

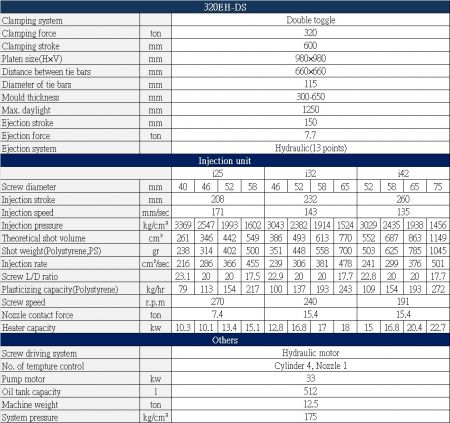

EH-DS 320 ton Specification Table

-

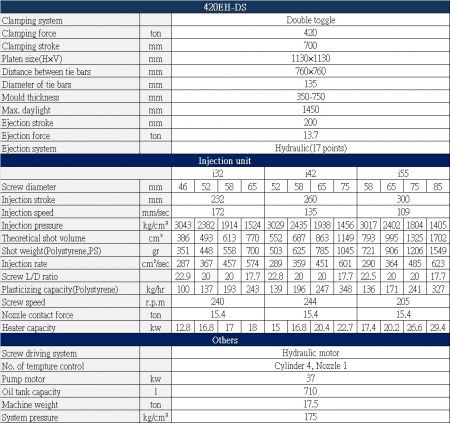

EH-DS 420 ton Specification Table

-

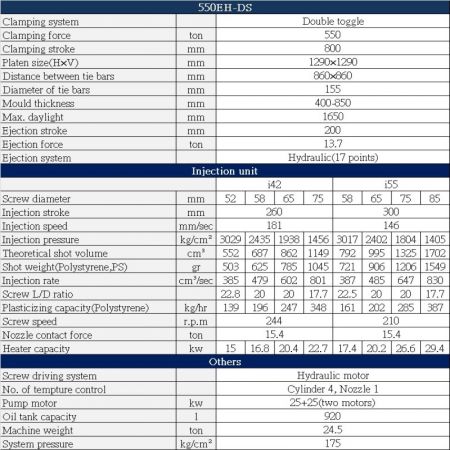

EH-DS 550 ton Specification Table

-

- Related Products

-

-

Small Size Hydraulic Plastic Injection Molding Machine

EH Series (50~140 TON)

The 50ton to 140ton Small-size Hydraulic Plastic Injection Molding Machine comes with an electro-hydraulic control system by the Rexroth solenoid and proportional pressure relief valve (both with Lvdt). The high-response hydraulic pressure and flow control system can quickly changeover to every injection stages command given by the user is needed. The hydraulic power resource is from the induction motor coupled with a vane pump, it is more capable of producing long hold pressure time (more than 60sec) products. If you need more detail of product information or buying consultation, please contact us.

-

Small Size Hybrid Plastic Injection Molding Machine

EH-DS Series (50~140 TON)

Small size Hybrid Injection Plastic Machine range from 50ton to 140ton equips the servo energy saving system, which achieves an outstanding energy-saving effect. The Hydraulic system with a rapid response and pressure output linear feature, easy to reach every requirement given by the user. Our Injection Machines can provide stable pressure when a high flow rate is required during the production. It saves energy during the low pressure output and the product cooling. Comparing with the conventional hydraulic system, it saves 60% energy consumption. It has a perfect pressure curve repeatability, and still keep the advantage of conventional hydraulic system, that has the ability to keep the pressure at 140kg/cm2 at least 30 sec. with low oil flow, it gives a huge competitiveness of thick products to prevent shrink, bubblers, jetting, etc. If you need more detail of product catalog, please reach out to us.

-

Medium and large size Hydraulic Plastic Injection Molding Machine

EH Series (180~750 TON)

Medium and large-size Hydraulic Plastic Injection Molding Machines ranging from 180ton to 750ton has the mainly hydraulic system configures an Electro-hydraulic proportional system to control the oil flow and pressure. It has responsive and high-consistency features. Via the Lvdt spool receives the feedback signal and modifying output, lets the users get a hydraulic pressure closer to the actual situation, and helps the users grasp the control of injection parameters. The power resource is from a double fixed vane pump. The main hydraulic system can provide a high-flow source via pumps' confluent, which gives an advantage to booting up the speed of the machine. The traditional-hydraulic system has two features, one is high-pressure resistance, and second is it can provide a long holding time. So the traditional injection machine is more suitable for making thick parts, transparent parts, products that require a smooth surface, or materials that need high-pressure holding. If you need more detail of product information or buying consultation, please contact us.

-

Medium and large size Hybrid Plastic Injection Molding Machine

EH-DS Series (180~750 TON)

The Hybrid Plastic Injection molding machine (180ton to 750ton medium and large size) equips a high-performance servo motor, which also achieves an outstanding energy-saving effect. With a rapid response and pressure output linear feature, easy to reach every requirement given by the user. It reduces the motor r.p.m when during the low flow is required and the product cooling to save the energy consumption. Comparing with the conventional hydraulic injection machine, it saves 60% energy at least.

-

- Files Download

-

-

EH-DS 50-110 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.

-

EH-DS 140-250 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.

-

EH-DS 320-550 Specification Table

50ton to 550ton plastic injection molding machine, according to the size, thickness and injection weight of the mold, you can select the type of the injection machine that best meets your needs. If you still have questions after consulting the information, please do not hesitate to ask us, we will be happy to help you.

-