What kind of services can I expect from purchasing injection machine?

Our technical team has a wealth of plastic injection molding experience that can quickly clarify your production problems.

Generally, customers with injection molding experience have the ability to adjust the machine to the best production state. For this type of customer, after the machine assembling and testing, it can be handed over.

However, some customers may lack injection molding experience, or they may be foreign customers. Top Unite assists in purchasing axillary equipment, such as a robot arm, molds, in-mold labeling, packaging machines, etc..., this kind of customer will want Top Unite to integrate the equipment into the injection machine and conducts trial production to confirm that the different equipment can be perfectly integrated and the production line goes smooth and unimpeded. After the injection machine is delivered, it can be put into production immediately.

Professional consulting services

Top Unite technical team has a wealth of market experience and specializes in plastic injection molding. We can quickly clarify your production problems and difficulties, immediately give perfect planning and advice, and provide a full range of technical support, so that our customer group can Put into production with peace of mind.

Perfect, professional and immediate maintenance service

When there is a problem in the production process of the injection machine, the customer can contact the purchase window to explain the situation directly. If the problem is not complicated, the contact window will guide how to detect through the communication device, and quickly eliminate the problem to ensure that your machine can quickly back into the production line.

If the problem is more complicated or involves the replacement of parts, it immediately arranged to enter the maintenance process, and the maintenance person will come to the factory to assist. The problem will be eliminated as soon as possible to reduce loss.

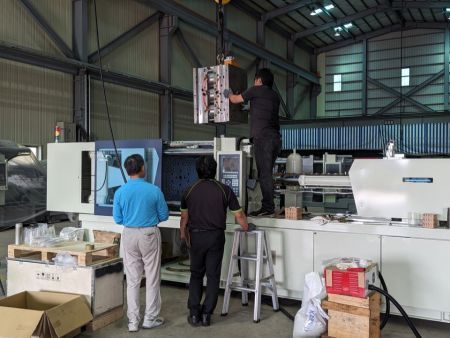

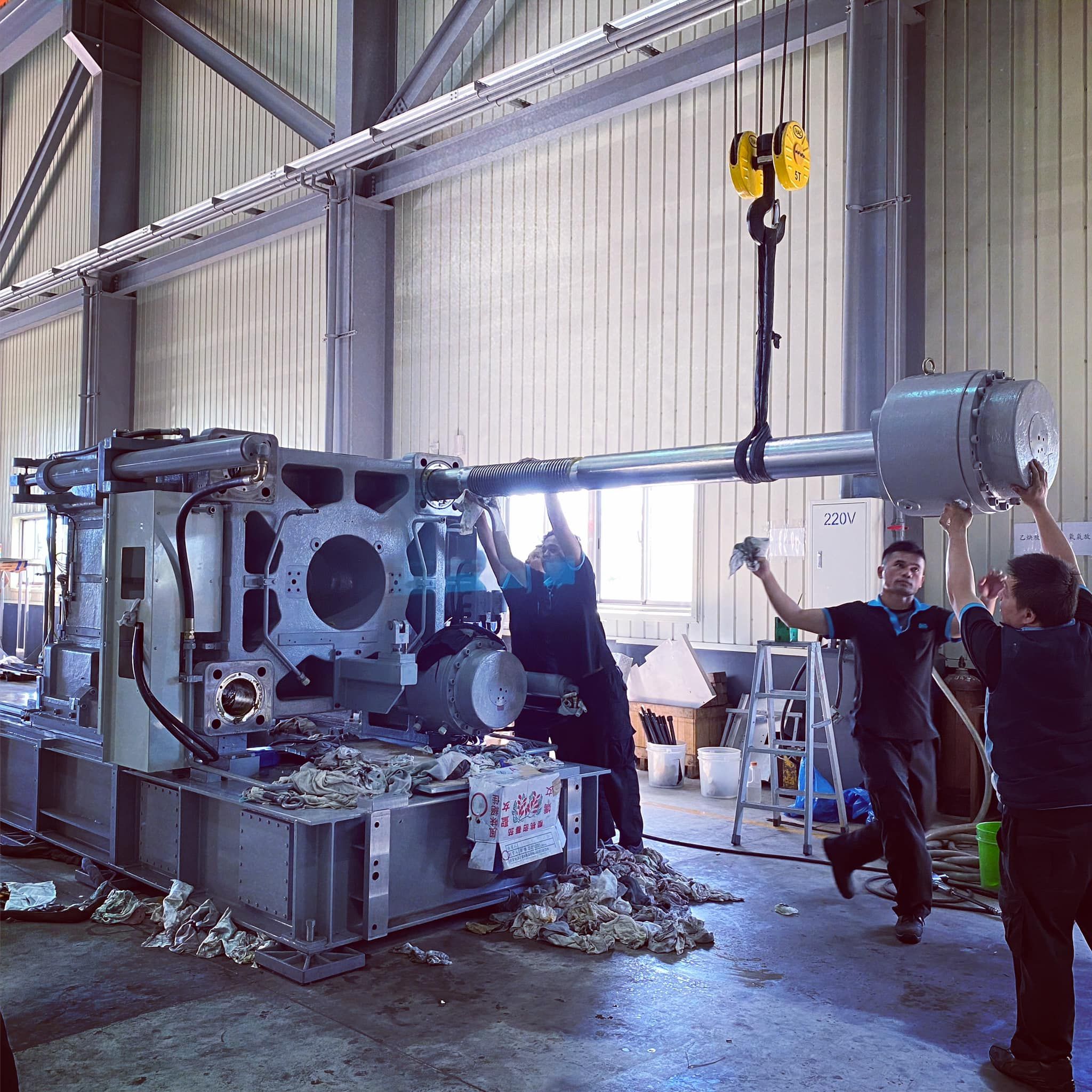

Photo Gallerys

- Injection molding machine exported to Peru, Top Unite technicians assisted in trial molding.

- Plastic injection molding machine exported to Peru, Top Unite technicians assisted in testing.

- High-speed plastic injection molding machine capable of producing disposable PP cups for the airline industry.

- Disposable PP/PS cups injection molding production line.

- Related Products

Hydraulic Plastic Injection Molding Machine

EH-DS Series (50~750 TON)

The hydraulic plastic injection molding machines has advantage that we provide back pressure to every action by limiting the oil return flow that decreases affection by inertia increases the hydraulic fluidity stability from a high-speed to stop condition. With this advantage, we achieve the precise level of the electric injection molding machine. Furthermore, we still keep the hydraulic injection molding machine's original advantage of high holding pressure ability and stable linearity pressure output. If you need more detail of product information or buying consultation, please contact us.

The Advanced Engineering Plastic Injection Molding Machine

EH Series (50~750 TON)

Customized plastic injection molding machine is designed for advanced engineering plastics. In recent years, the quality standard of plastic products getting strict than before. For meeting these standards, lots of new plastic have been launched in the past few years, especially advanced engineering plastics. The advanced engineering plastics require acid and alkali proof, high-temperature resistance, halogen-free, and high structural strength. By upgrading the hydraulic system output pressure to 200kg/cm², improve the cooling system, build a special screw barrel, and increase the motor power and heater capacity, the Top Unite achieves a high-performance injection molding machine for advanced engineering plastics. If you need more detail of product information or buying consultation, please contact us.

The High-Efficiency Synchronous Plastic Injection Molding Machine

EHIII Series (50~750 TON)

The high-efficiency synchronous plastic injection machine is designed to meet the comprehensive needs of customers for cost, production capacity, and stable production process. The injection unit and clamping unit are individually controlling by a dual hydraulic system, these two systems could synchronize dosing and mold-opening to match a perfect production timing. Through comprehensive structural improvements and system upgrades, this model can significantly reduce production costs, shorten production cycles and rising output. If you need more detail of product information or buying consultation, please contact us.

Polycarbonate Plastic Injection Molding Machine

EH-DS Series (50~750 TON)

Plastic Injection molding machine has directed the characteristic of polycarbonate, strengthens the injection unit to get higher injection pressure that maintains a stable production and effectively preventing wavy or streaks caused on the product surface.This series of models build-in a Polycarbonate-transparent special-purpose material barrel, which surfaces with the chromium plating process, and an exclusive L/D ratio design, to prevent black spots and yellowing on the product and improve production quality. If you need more detail of product information or buying consultation, please contact us.

Plastic-Caps Special Plastic Injection Molding Machine

EH-DS Series (50~750 TON)

Plastic-cap special plastic injection molding machine is designed against the food packaging industry. The machine builds in a PP and PE special double thread material barrel. It helps to compound with color masterbatch during the material is plasticizing to reduce the defective products.To save more time, we place a proportional valve to boot up the speed in the mold closing/opening and make it more accurate to protect your mold. Meanwhile, we strengthen the clamping toggle structure to bear the high pressure from high-speed mold closing/opening which extends the service life. If you need more detail of product information or buying consultation, please contact us.