How does plastic injection machine achieve high performance, high precision and high stability?

Top Unite full range of plastic injection molding machines are high-performance machines, with excellent injection performance, more accurate shooting stroke, the mechanical operation is extremely stable, high repeatability, and low maintenance rate, longer service life, not only to fully meet the needs of all types injection molding industry but also to significantly reduce customer production costs.

Focus on the details to achieve professional

In terms of quality control of the machine, for presenting the best injection machine to the users, we put a strict attitude on the components choosing, the TopUnite adheres to the use of manufactured by high-quality hydraulic parts. To present the perfect machines to every user, the whole assembling step is detecting by the engineer with precision measuring equipment to make sure every structure works stability, smooth, and safe that ensure every high-quality component could bring maximum effect to the machine.

Multiple hydraulic technique

Top Unite provides multiple hydraulic systems to meet various injection molding industry that raises productivity. From conventional hydraulic to servo energy-saving systems, we could customize for you to raise the pressure limit or hydraulic flow. By used more accurate, efficient techniques to build the basis of high-quality plastic products.

Sturdy, reliable clamping structure

Top Unite attaches great importance to the stability of the structure and design of the clamping unit. To ensure the strength of the template to meet injection molding needs in different industries, TopUnite Machinery's full range of injection molding machines uses high-rigidity platen. Even under extremely high injection pressure and speed conditions, the platen will not be deformed or broken to avoid the product flash, improve the product quality, and prolong the machine's lifetime.

Changeable injection unite

Top Unite injection molding machine provides 3 types of injection units for the user to choose from. With the different products, you can have an upgrade unite to get more injection pressure for a hard plastic product, or a small unit to get a higher injection speed for a thin wall product.

Our Technology Advantage

The Injection Machines with the thick clamping unit decrease the flashes of products.

The Injection Machines with a user-friendly PLC System makes users operate easily.

The precision hybrid injection machine with low current consumption.

The High-Speed Response Injection Machine is easy to meet the requirements.

- Related Products

Small Size Hybrid Plastic Injection Molding Machine

EH-DS Series (50~140 TON)

Small size Hybrid Injection Plastic Machine range from 50ton to 140ton equips the servo energy saving system, which achieves an outstanding energy-saving effect. The Hydraulic system with a rapid response and pressure output linear feature, easy to reach every requirement given by the user. Our Injection Machines can provide stable pressure when a high flow rate is required during the production. It saves energy during the low pressure output and the product cooling. Comparing with the conventional hydraulic system, it saves 60% energy consumption. It has a perfect pressure curve repeatability, and still keep the advantage of conventional hydraulic system, that has the ability to keep the pressure at 140kg/cm2 at least 30 sec. with low oil flow, it gives a huge competitiveness of thick products to prevent shrink, bubblers, jetting, etc. If you need more detail of product catalog, please reach out to us.

Medium and large size Hybrid Plastic Injection Molding Machine

EH-DS Series (180~750 TON)

The Hybrid Plastic Injection molding machine (180ton to 750ton medium and large size) equips a high-performance servo motor, which also achieves an outstanding energy-saving effect. With a rapid response and pressure output linear feature, easy to reach every requirement given by the user. It reduces the motor r.p.m when during the low flow is required and the product cooling to save the energy consumption. Comparing with the conventional hydraulic injection machine, it saves 60% energy at least.

Small Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (50~140 TON)

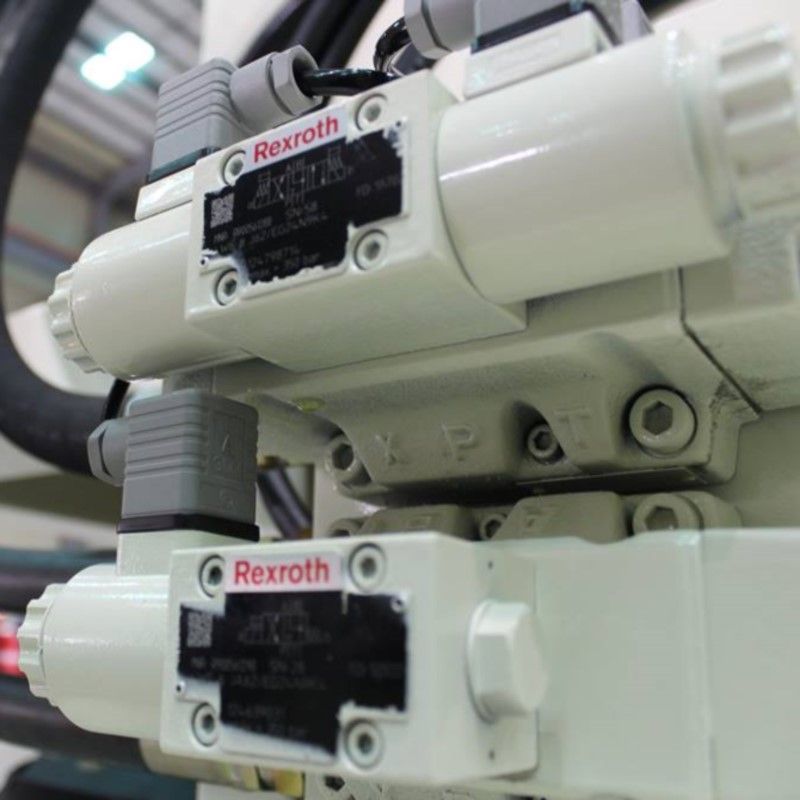

The 50 ton to 140 ton High-Speed Hybrid Plastic Injection Machine with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.

Medium and Large Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (180~750 TON)

The High-Speed Hybrid Plastic Injection Machine is designed with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.