The plastic injection machines with the thick clamping unit decrease the flashes of products

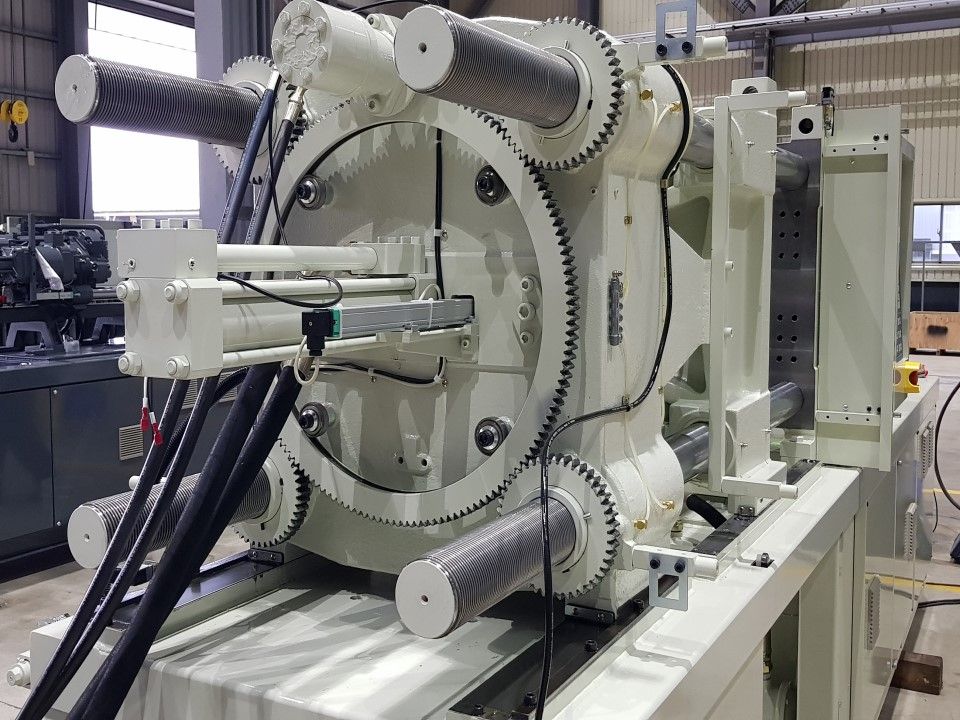

Top Unite is committed to building a sturdy clamping system, we are aware importance of clamping is the key factor to influence the product yield. Therefore, we focus on the structure of the clamping system, from chooses of materials, mechanical processing, and assembling to achieve a clamping system that is high-resistance to resist the force from the injection to avoid flash causing and raise production yield.

High-Rigidity Mold Platen

FCD-600 spheroidal graphite cast iron with thicker plate achieves 600 ~ 750 N/mm² high tensile strength. Even under extremely high injection pressure and speed situation, which without any bending or deforming that increase final product quality and machine lifetime.

Movable Slide Platen

The slide is made from S-60C high carbon steel with High-frequency heat hardening surface treatment coupled with IKO roller bearing made in Japan; it reduces friction and brings silky smooth mold opening and clamping action.

- High-Rigidity Mold Platen

- High-Rigidity Mold Platen

- S-60C steel with High-frequency heat hardening surface treatment

- S-60C high carbon steel coupled with IKO roller bearing made in Japan

Automatic Centralized Lubrication System

The toggle lubrication system is by using Japan LUBE greasing system with automatic greasing filling per 8000 mold clamping. Dosing valve discharges amount within 3% tolerance, which can ensure fully lubricated of each greasing point and prevent greasing oil from solidifying.

Mold Adjustment Mechanism

Mold Adjustment Mechanism with sturdy gear and high torque hydraulic motor has high strength and low clearance, which can reduce adjusting time and increase accuracy.

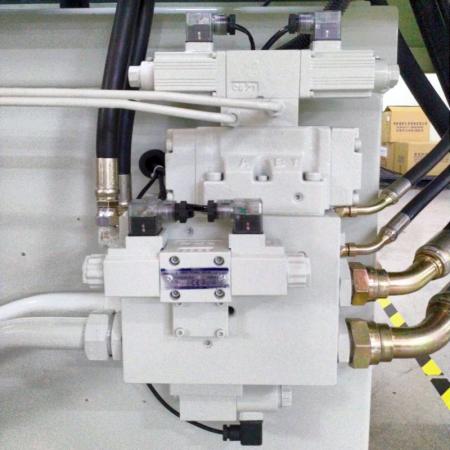

Mold Adjustment Motor with Brake Unit

Cycloidal motor with brake unit for mold thickness adjustment motor. Use the shuttle valve to control the brake unit. Braking torque is up to 320Nm that can ensure mold can keep in same position and prevent dislocation-causing flash of product.

- Top View of Toggle

- Toggle and Crossed Supporting Structure

- Japan Lube Grease System

- Mold Adjustment Mechanism and Cycloidal Motor with Brake Unit

Mold Opening / Clamping Unit

Mold open / clamping switch is controlled by Japan Yuken proportional solenoid valve, which has ability to hold heavy mold in stable position when opening. It can increase the stability of the platen location point, so that if when use suction to take the product from the mold, or use the IML to put label inside the mold, proportional directional control valve can always make the mold daylight tolerance in only ±0.1mm to make sure product can correctly take out from mold or put label inside the mold.

- Amplifier for Yuken Proportional Solenoid Valve

- Yuken Proportional Solenoid Valve

- Clamping Oil System