How to avoid plastic injection machine to cause flash to product?

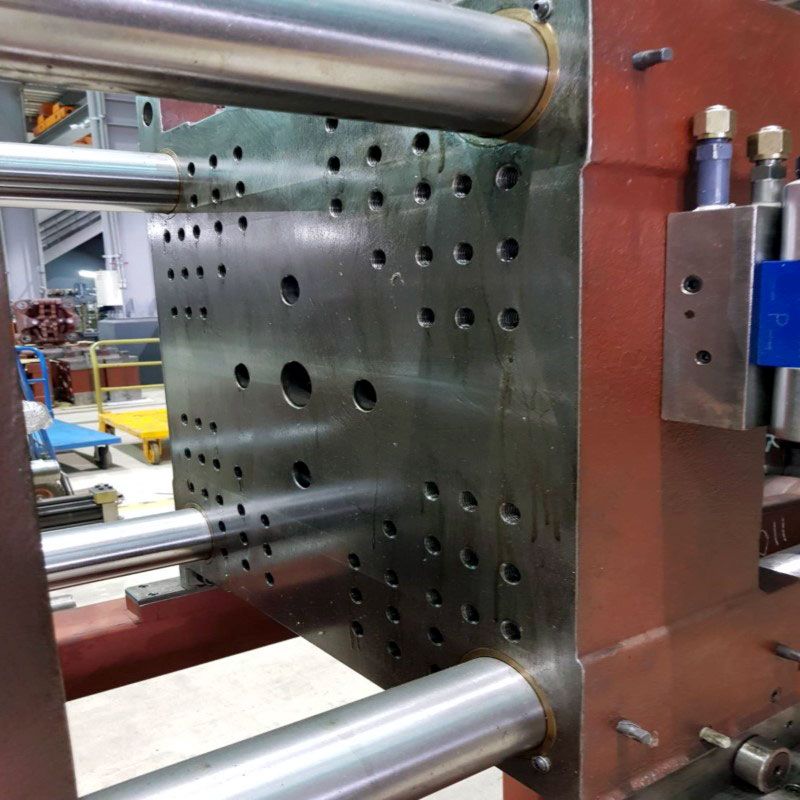

The problem of causes flash to the products is a lot, the key factor is the strength of the platen. If the platen is not strong enough to resist the pressure from the injection, it will cause the gap by the platen deforming, and this gap leads to melting plastic leaked that causes the flash to the products.

To ensure the strength of the template to meet injection molding needs in different industries, Top Unite full range of injection molding machines uses high-rigidity platen, using FCD-600 spherical graphite cast iron, which can achieve a high tensile strength of 600~750 N/mm². Even under extremely high injection pressure and speed conditions, the platen will not be deformed or broken to avoid the product flash, improve the product quality, and prolong the machine's lifetime.

Our Technology Advantage

- Related Products

Small Size Hybrid Plastic Injection Molding Machine

EH-DS Series (50~140 TON)

Small size Hybrid Injection Plastic Machine range from 50ton to 140ton equips the servo energy saving system, which achieves an outstanding energy-saving effect. The Hydraulic system with a rapid response and pressure output linear feature, easy to reach every requirement given by the user. Our Injection Machines can provide stable pressure when a high flow rate is required during the production. It saves energy during the low pressure output and the product cooling. Comparing with the conventional hydraulic system, it saves 60% energy consumption. It has a perfect pressure curve repeatability, and still keep the advantage of conventional hydraulic system, that has the ability to keep the pressure at 140kg/cm2 at least 30 sec. with low oil flow, it gives a huge competitiveness of thick products to prevent shrink, bubblers, jetting, etc. If you need more detail of product catalog, please reach out to us.

Medium and large size Hybrid Plastic Injection Molding Machine

EH-DS Series (180~750 TON)

The Hybrid Plastic Injection molding machine (180ton to 750ton medium and large size) equips a high-performance servo motor, which also achieves an outstanding energy-saving effect. With a rapid response and pressure output linear feature, easy to reach every requirement given by the user. It reduces the motor r.p.m when during the low flow is required and the product cooling to save the energy consumption. Comparing with the conventional hydraulic injection machine, it saves 60% energy at least.

Hydraulic Plastic Injection Molding Machine

EH-DS Series (50~750 TON)

The hydraulic plastic injection molding machines has advantage that we provide back pressure to every action by limiting the oil return flow that decreases affection by inertia increases the hydraulic fluidity stability from a high-speed to stop condition. With this advantage, we achieve the precise level of the electric injection molding machine. Furthermore, we still keep the hydraulic injection molding machine's original advantage of high holding pressure ability and stable linearity pressure output. If you need more detail of product information or buying consultation, please contact us.

Thin-Wall Plastic Injection Molding Machine

EHIII-DS Series (50~750 TON)

Thin-wall plastic injection molding machine is manufactured by increasing the injection speed and the stability of injection, the thin-wall injection machines effectively avoiding short shots and flashes on the product to improve product quality.We upgrade the thin-wall injection machines control components to get a higher injection speed that ensures the injected melting plastic material could reach the entire mold cave before it getting solidification which decreases the short-shot products happened. If you need more detail of product information or buying consultation, please contact us.